Jelly Interlining

Diversified, one-stop, 23 years of experience

National Advisory Hotline:

+86-769-22019821

Fax:

E-mail:terence@dgjelly.com

Add:No.1 New District of Makeng, Xinmalian Section, Dalang Town, Dongguan City, China

[Interpretation] 1, cloth sewn on the collar, the shoulders of the clothes, the cuffs and the inside of the waistband. 2. Additional canvas sewn to the frictioned portion of the sail.

1. Interlining effect

The lining cloth is used to set off the fabric, improve the performance of the garment, and plays a great role in the beautiful appearance of the garment, and promotes the garment to have a perfect shape, which can make up for the insufficient performance of the fabric.

Second, the lining classification

Clothing linings are generally divided into non-woven and woven.

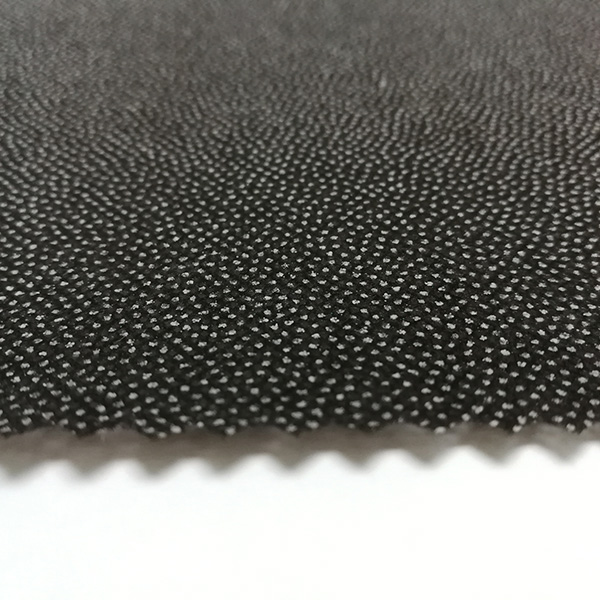

1. Non-woven lining. As the name suggests, it is a cloth that has not been formed by weaving.

Process principle: The chemical fiber is coated with a high temperature and high pressure to form a base fabric. Then, a layer of hot melt adhesive is applied to the surface of the base fabric through a coating machine, and then dried to form the nonwoven interlining used.

How to use: Place the glued side of the lining on the fabric, then use a bonding machine or iron to heat the glue on the lining to achieve the effect of bonding to the fabric.

Features: cheap, soft to the touch, but not washable.

2. There is a woven lining. Commonly used equipment is a key loom and a water jet loom, and the polyester is made into a base fabric by weaving. It is characterized by strong pulling force and good elasticity.

Regarding the rubber of the lining cloth, the powder used in the market is usually dusting glue, which is characterized by large amount of glue and simple production process; the disadvantage is that because of the large amount of glue, it is easy to produce a phenomenon of penetration. It has now been eliminated.

The most advanced is the two-point process without foundation, which is characterized by easy control of the amount of glue, strong adhesion, washing resistance and other special treatments. It is now used by most manufacturers.

Classified by purpose

1, shirt adhesive lining: requires water wash, shrinkage rate is small, stiff and flexible. The base fabric is made of woven fabric with PE or PET glue.

2, the outerwear adhesive lining: required to be resistant to dry cleaning and washing, soft, flexible. The base fabric can be woven, knitted or non-woven, with PA, PET or PVC glue.

3, leather adhesive lining: requires low pressing temperature, soft hand feeling, poor washing performance. The base fabric is made of woven fabric, heavy textile, and EVA or PA glue.

4, shoes and hats and decorative adhesive lining: the requirements of low pressing temperature, low price, poor washability. The base fabric is made of non-woven fabric, woven fabric or foam, and EVA, PE or PVC glue can be used.

Third, the production process of the lining cloth

Singeing - cold pile - de-cooking and bleaching - drying - tenter setting - resin - drying - coating - packaging inspection.